Articles by Aggie Lotz

Strategic Solutions

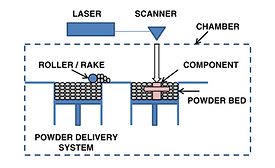

Adhesive bonding opportunities are exponentially increasing with the design complexities of polymer and metal additive manufacturing.

Read More

Strategic Solutions

Collaboration and Innovation for Sustainable Packaging

Ink, adhesive, paperboard, film, and other material suppliers need to understand relevant certifications and processes in order to adhere to recycling or composting standards.

September 4, 2020

Strategic Solutions

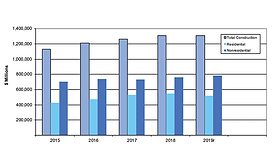

Market Dynamics for North American Sealants

Through 2019, the building and construction market was a sealants volume leader, followed by assembly operations and transportation.

August 17, 2020

Strategic Solutions

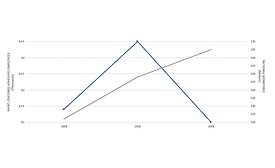

Switching Production to Satisfy Shifts in Demand

Production cycle planning and excess capacity can yield unexpected advantages.

July 7, 2020

Strategic Solutions

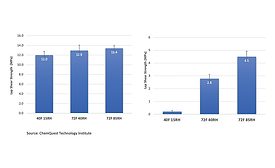

Third-Party Validation of Adhesive Performance

This second installment of a two-part series higlights the value proposition of independent material testing and validation to high-value end-use markets.

March 27, 2020

Strategic Solutions

Evolving Hybrid Adhesives

This first installment of a two-part series highlights the value proposition of today's adhesive chemistries and curing methods to high-value end-use markets.

February 13, 2020

Strategic Solutions

Market Opportunities for Structural Adhesives

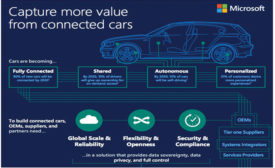

Structural adhesives’ volume is expected to increase as pure electric vehicles displace internal combustion engines in the marketplace.

May 1, 2019

Strategic Solutions

Latin America’s Quest for Innovation

Several drivers are at play for the development of new adhesive technologies in Latin America.

March 6, 2019

Strategic Solutions

Beyond Adhesion: Disruptive Innovation’s Impact in Transportation Adhesives

Part two of this series compares consumption trends in automotive powertrain adhesives and sealants to those of pure electric drivetrains.

April 6, 2018

Strategic Solutions

Beyond Adhesion

Disruptive innovation has impacted transportation applications of adhesives and sealants.

March 9, 2018

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing