Home » Keywords: » sealants in aerospace

Items Tagged with 'sealants in aerospace'

ARTICLES

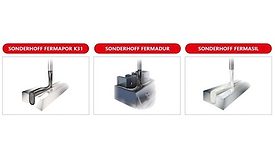

New Research Investigates Innovative Possibilities for Process Monitoring of Sealants

Inline-capable measuring techniques should enable quality assurance of applied sealants in the future.

December 20, 2024

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1709670950&width=275)

.jpg?height=168&t=1704834340&width=275)