Home » Keywords: » lightweighting

Items Tagged with 'lightweighting'

ARTICLES

2022 Voices from the Top: Adhesive & Sealant Industry Insights

To develop Voices from the Top, we reached out to key leaders at some of the top adhesive and sealant companies to get their insights on a number of issues.

June 27, 2022

Strategic Solutions

The Wonderful Wide World of (Pressure-Sensitive Adhesive) Tape

The pressure-sensitive tape market continues to expand, with global growth rates predicted to be over 6% through 2030.

April 26, 2022

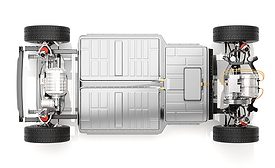

Electric Vehicle Market Advances Generate Adhesive Technology Innovations

As the electric vehicle market evolves and develops, adhesive manufacturers create new technologies to meet these needs.

February 11, 2022

Market Trends

Strong Growth Projected for Automotive Adhesive Tapes

Several key trends will help drive the 6.1% CAGR expected for automotive adhesive tape revenues through 2028.

February 9, 2022

Hexion’s Composite Technology Wins Two Awards from SPE

Hexion's composite technology was recognized in awards within the North American and Central European divisions, as well the Grand Award.

November 26, 2021

DuPont Breaks Ground on New Facility in East China

The facility will produce a range of materials to advance applications for electrification and lightweighting in support of growing demand for DuPont’s automotive adhesives.

November 22, 2021

Seven Ways Adhesives Push Electric Vehicle Design Forward

Adhesives offer significant advancements in electric vehicle safety, cost, durability, and performance.

August 2, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing