Home » Keywords: » anaerobics

Items Tagged with 'anaerobics'

ARTICLES

Maintenance, repair, and operations engineers can benefit from the sustainability and operational benefits of engineering adhesives.

Read More

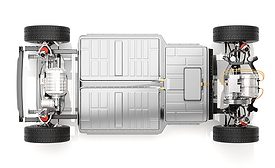

Electric Vehicle Market Advances Generate Adhesive Technology Innovations

As the electric vehicle market evolves and develops, adhesive manufacturers create new technologies to meet these needs.

February 11, 2022

Ask Dr. Dave

Vibration- and Shock-Resistant Adhesives

Which adhesives can resist serious vibration and shocks?

October 20, 2021

BOSTIK: Anaerobic Engineering Adhesives

These adhesives offer a number of advantages over mechanical solutions, such as long-term reliability, increased versatility of application, and protection against corrosion.

October 7, 2021

Ask Dr. Dave

Understanding Two-Component Adhesives

Why do we have to use two-component adhesives and meter/mix equipment in our assembly and repair operations?

March 16, 2021

Ask Dr. Dave

Repairing Leaks in a Fire Sprinkler System

We have some pinhole leaks in our fire sprinkler system in a large residential apartment block. Can you recommend a sealant that will stop the leaks to give us some time before we have to replace the entire system?

October 2, 2020

Marine Applications for Adhesives and Sealants

Today’s marine adhesives and sealants provide strong lightweight bonds to structural components and watertight sealing between substrates.

September 8, 2020

Ask Dr. Dave

Solvent-Based Adhesives

I was brought up using solvent-based adhesives, but they don’t seem to be as common these days. Is it just a safety issue? Are any of these adhesives still available?

August 4, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing