Advanced UV-Adhesives Help Industry Stick to Future EU Labeling Laws

Advanced cyanoacrylates will enable manufacturers to meet current and future sustainability and ESG reporting needs, and comply with future labeling requirements.

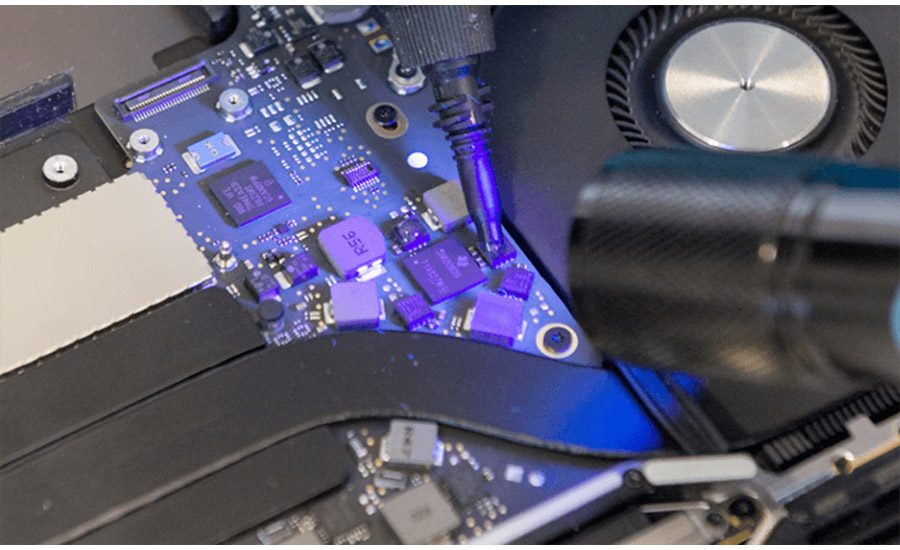

images courtesy of Bostik

images courtesy of Bostik

Environmental, social and governance (ESG) regulation is shaping tomorrow's chemical industry, which is a core part of the value chain of many manufacturing sectors. As government agencies across the globe try to de-risk manufacturing by removing chemical hazards from the supply chain, the chemical industry is having to innovate.

Many commercial photoinitiating (PI) substances used in light curing cyanoacrylate formulations are classified as Sensitizing and/or CMR (Carcinogenic, Mutagenic, Reproductive Toxin). Formulations that contain these substances above a specified threshold are also classified and require hazard statements and pictograms on their Safety Data Sheets (SDS) and labels to provide guidance to the user on the risks associated with using these products. A widely commercialized photoinitiator, TPO, is expected to have a harmonized classification update to Reproductive Category 1B in the summer of 2023. In fact, the European Chemicals Agency (ECHA) recently announced an intention to identify TPO as a Substance of Very High Concern (SVHC). It is expected that this will occur later this year. While this is an EU regulation, the impact is much wider — customers internationally across Asia and AMAS will also likely restrict or ban the use of SVHC in their products.

Bostik’s Bond2Bond™ Light Lock range of adhesives are not classified as hazardous in either the European Union or the United States. They were designed using an innovative photoinitiator in anticipation of such changes and will comply with the regulatory changes about to be introduced.

These adhesives enable manufacturers, for the first time, to use cyanoacrylates in domestic product applications such as consumer electronics, and in products that will be subject to harsh environmental conditions. These advanced cyanoacrylates will ensure that manufacturers can meet their current and future sustainability and ESG reporting needs, and comply with future labeling requirements.

Designed for Safety

On fast-running production lines, cyanoacrylate adhesives are often rapidly cured using UV light. This is because excess adhesive outside of bonded joints can either spoil the look or function of the end products or cause production issues, or both. Dust sticks to the wet adhesive, and the excess can cause electronics to fail; or it unintentionally bonds components to other parts, machinery, or an operator's hands during production. UV light, however, is hazardous to workers and energy-intense for manufacturers to use.

The innovative photoinitiator used by Bostik, when added to cyanoacrylates, enables curing of the adhesive in just a few seconds when exposed to UV visible blue light (405-420 nm) and is safer for workers. Blue light only requires 16 milliwatts of power per square centimeter, which is one-tenth of the power needed for standard UV radiation and means LED lights can replace old mercury bulbs. LEDs emitting visible light are also far more energy efficient than the standard UV systems typically used today.

These UV-visible cyanoacrylates, part of Bostik’s Born2Bond range of adhesives, are not only more energy efficient for manufacturers, but they also help to increase efficiencies on the production line. Anyone trying to position or adjust the precise application of the adhesive on small electrical components, for instance, can see exactly where it is being placed, and ultimately that helps to reduce waste product. The speed of the cure is also important for running an efficient assembly line; the faster the cure, the higher the manufacturing yield. Advanced UV cyanoacrylates enable a “flash cure” — one that is double the speed of a standard UV cure.

Today, curing adhesives in bulk and in gaps is even easier and faster, with thicknesses of up to 10mm being cured in just 10 seconds. Those qualities — depth and speed — mean manufacturers can bond parts with bigger gaps between them or create beading that is bulky or irregular in thickness and shape, and so offers manufacturers greater flexibility in the design of new products.

Designed for Durability

Typically, ethyl cyanoacrylates give off a vapor, which is a nuisance to manufacturers in two ways. First, the vapor is a health hazard for workers, causing irritation to their eyes and skin. Over time workers can become desensitized to the odor of these adhesives, increasing the chances of unknowingly being exposed to the health risks. Consequently, UV ethyl cyanoacrylates can only be used in highly ventilated environments and cannot be used on large surface coatings or domestic environments. Second, these products require hazard statements and pictograms on their EU and U.S. Safety Data Sheets and labels to provide guidance to the user on the risks associated with using these products, but those with a methoxyethyl cyanoacrylate formulation do not.

For manufacturers, the vapor is also a nuisance because it causes a phenomenon known as blooming. During production, the vapor condenses on the surface of a product or component, leaving behind a white stain. For luxury goods, perfume bottles and jewelry, it is unsightly; for consumer electronic and audio products, it can interfere with sensitive electronic components, causing them to fail. Within the above-referenced adhesives, the methoxyethyl cyanoacrylate was designed to be vaporless. Consequently, there is far less blooming with these advanced cyanoacrylates, resulting in less product spoiling and less production waste.

Instead, advanced methoxyethyl cyanoacrylates produce a colorless, dry-to-the-touch glossy film. These adhesives have low odor and emit low levels of vapor, so they can be used to coat large surfaces such as kitchen units and work surfaces, or car panels, where previously this was not possible. They can also reduce production waste. For example, when cars are painted, defects in the substrate cause small holes to appear in the surface. An advanced UV cyanoacrylate can be used to fill these holes and, because it dries to a tack-free surface, can then be sanded and repainted. That means automotive panels can be repaired rather than replaced, and the repair is durable.

Designed for the Future

The viscosity of the advanced UV cyanoacrylates can be changed using the appropriate thickeners or solvents so that they are fit for purpose and for the application process. They can be thinned down to be used in surface coatings (or if the production process needs rapid curing or drying in electronic encapsulation), or they can be thickened to be used in bulk and gap filling for the creation of gaskets and seals.

In the future, methoxyethyl cyanoacrylates will provide manufacturers with some unique opportunities with new technology, such as 3D printing. These adhesives are extremely tack-free and compatible with these new production technologies, which are only just being incorporated into manufacturing processes.

Meanwhile, these innovative UV visible cyanoacrylates offer manufacturers a range of new product applications, give them the ability to meet tomorrow’s labeling requirements today, and ultimately help fulfill the promise of a more sustainable, global supply chain.

For additional information, visit https://born2bond.bostik.com/en/home.

Article images courtesy of Bostik.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!