How Alternative Thermally Conductive Gap Fillers Improve EV Battery Sustainability

As the automotive industry works to increase electric vehicle (EV) options and meet rising consumer demand, it’s important for manufacturers to consider how their chosen EV battery materials impact the battery’s overall sustainability, in addition to meeting performance requirements. Using thermal interface materials, such as thermally conductive gap fillers, is one way to achieve EV battery performance goals; gap fillers help prevent the battery from overheating. However, common gap filler options can pose certain sustainability challenges. While EVs are fundamentally designed to help reduce environmental impact, these gap fillers can make it difficult for EVs to reach their full potential overall. Therefore, manufacturers should consider an alternative option.

Understanding the Role Thermally Conductive Gap Fillers Play in EV Battery Performance

Thermally conductive gap fillers are designed to fill air gaps between battery cells and cooling systems, providing electrical insulation to the rest of the battery module and assisting in proper thermal management. When a battery uses gap fillers, it is less susceptible to short circuiting and overheating, both of which can negatively impact overall battery lifespan. Because the battery’s lifespan can be longer than a battery made without them, gap fillers help reduce material usage and waste production. They also offer temperature resistance, which allows the battery to operate at different temperatures for charging, discharging, and operational use.

Key Sustainability Challenges with Common Thermally Conductive Gap Fillers

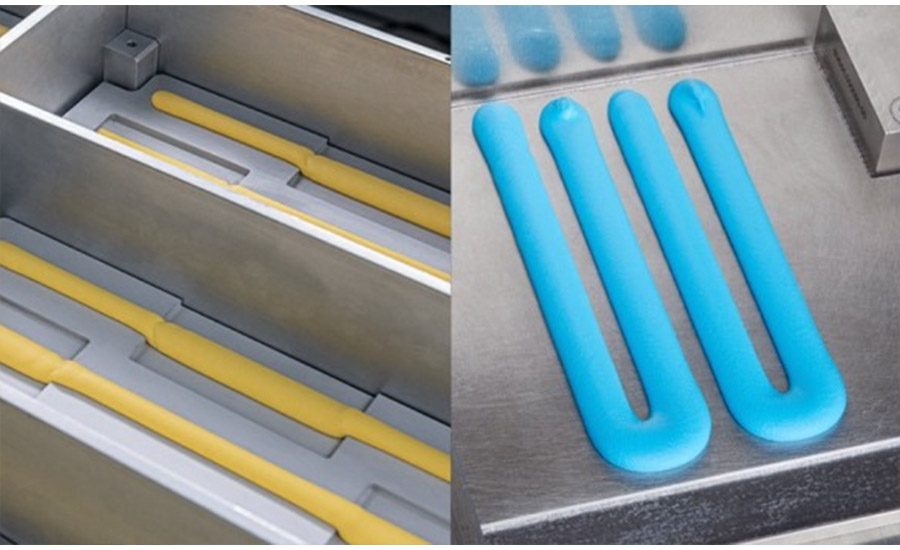

Production Inefficiencies: While common gap fillers’ attributes help the battery meet end-use performance requirements and can support sustainability initiatives to some extent, their formulation can cause production inefficiencies. For example, many gap fillers are based on aluminum oxide and have a Mohs hardness of nine out of 10. This causes the gap fillers to be abrasive, putting strain on dispensing machines and often causing leaks to the valves. As a result, it requires additional equipment maintenance and downtime to address. Other gap fillers are in a solid gap pad format. This, too, can cause efficiency challenges. Solid gap pad fillers most often rely on manual compression to remove the air or require complex equipment to apply constant pressure. To do this effectively and without error, manufacturers must take extensive time to ensure all air has been removed. If it’s not, then the battery may have poor thermal connection and be more susceptible to overheating, causing safety risks and material waste.

Waste Generation: Many traditional gap fillers are based on silicone. While silicone-based gap fillers offer high strength due to their thermal and chemical stability, this stability poses battery component disassembly challenges. Silicone-based gap fillers can either leave behind a hard-to-degrade residue or fully render the component unable to be separated down to its sub-parts. This causes the battery component to ultimately be discarded and replaced in full, which contributes to landfill waste generation in addition to increased material usage.

How Alternative Thermally Conductive Gap Fillers Overcome Key Sustainability Challenges

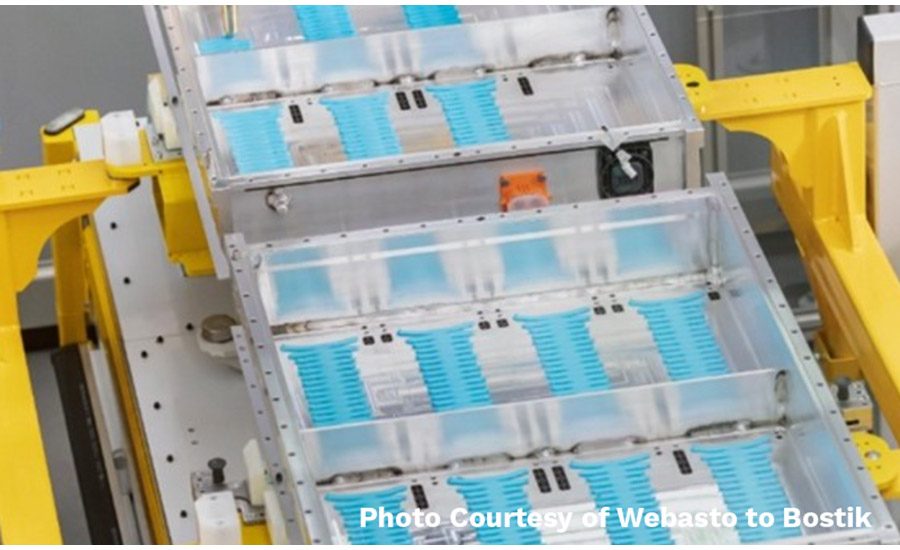

Increased Production Efficiencies: Compared to common options, gap fillers that are based on aluminum tri hydroxide have a Mohs hardness of three. These alternative gap fillers are a much lighter and softer liquid material. As a result, they can pass through the dispensing machines easily and with little to no abrasion, keeping equipment maintenance to a minimum. Additionally, because they are soft liquids to start, they easily support fast automation processes for air removal. No complex equipment or manual processes to provide constant pressure is needed. Instead, they can be immediately compressed and then cured before becoming stable, which streamlines efforts and reduces associated error likelihood as well as associated downtime costs.

Reduced Waste Generation: Alternative gap fillers are also available in one- and two-component options, both of which help contribute to less waste production compared to other gap fillers. When used in a one-component format, they are oil-based and do not cure. Instead, they maintain the same liquid viscosity throughout their lifespan, which aids in easy removability and enhances overall recyclability efforts. These alternative gap fillers are also available in a two-component format. The two-component format is silyl modified polymer (SMP) based and does cure; however, even so, these gap fillers still maintain a low bond strength. As a result, they are easy to remove when the battery module needs to be repaired, and manufacturers can disassemble the battery module down to its sub-parts and reuse them if needed to reduce overall waste generation.

Other Sustainability Benefits Associated with Alternative Thermally Conductive Gap Fillers

In addition to streamlining production as well as repair and removal processes, alternative gap fillers possess certain performance characteristics that help enhance overall sustainability. For example, SMP-based gap fillers have inherent flexibility and can crosslink due to the presence of reactive silyl groups in their molecular structure. This crosslinking begins during or shortly after application and continues to occur within the battery module over the course of the module’s lifetime as it charges and discharges. Therefore, the gap filler continually builds its durability, which can extend the battery’s longevity and increase sustainability.

This repeated crosslinking also allows the gap fillers to form a flexible, elastomeric network with relatively high thermal conductivity due to the nature of the silyl-based curing reaction and the resulting structure. Further, minimal shrinkage occurs, which helps prevent air gap formation. In addition to reducing likelihood of overheating and improving overall safety, a battery with low thermal resistance helps extend battery life and optimizes charging efficiencies, which both support a more sustainable battery overall.

Summary

As EV technology advances, the importance of manufacturing a sustainable, high-performing battery does as well. By choosing alternative thermally conductive gap fillers, manufacturers can streamline production processes and simplify battery module repair and recyclability, which are key components to improving sustainability.

Additionally, incorporating these gap fillers can be easy with the right supplier. Bostik, the adhesive solutions segment of Arkema, is a global adhesive supplier that recently acquired Polytec PT, a company known for its TIMs, such as alternative thermally conductive gap fillers. In addition to offering one- and two-component gap fillers, the company provides dedicated technical support to assist manufacturers in testing and troubleshooting needs. For more information, contact Bostik today.

Images within this article provided courtesy of Bostik.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!