Industrial Displays and Touch Panels

Displays are omnipresent nowadays. Not only are they found in portable devices such as mobile phones and tablet PCs, but they are also used in parking ticket terminals, ticket machines, and ATMs. Display requirements have escalated as continuously as the variety of applications; users now expect complete transparency and the utmost quality.

However, liquid crystal displays (LCDs) are difficult to read in bright surroundings (e.g., in direct sunlight). The reason for this is that the displays are often covered by a glass plate to protect them against vandalism. The sunlight is partly reflected at the interfaces, and these reflections superpose the generated image. This effect can be reduced by bonding the glass cover directly to the LCD using an index-matched adhesive. For this purpose, innovative adhesives have been developed that cure by a combination of light and humidity.* Reliable curing of adhesive in shadowed areas is possible.

Bonding provides additional benefits beyond improved readability. Contamination caused by dust between the glass plates is prevented. In addition, the glass plate will not fog up in humid surroundings. The ruggedness and resistance to vibrations and shock is also increased. Typical application areas include large-area displays in the automotive, aircraft and military industries.

*Developed by DELO Industrial Adhesives.

INDEX-MATCHED LCD ADHESIVES

The refractive index of these newly developed adhesives is matched to glass, which improves the readability of the display. This circumstance is confirmed by the following calculation based on the Fresnel formulas. If a light beam vertically hits a glass surface, the formula for the reflection coefficient R is applied:

R = (nglass-nair)2 / (nglass+nair)2

Assuming reflective indices of nglass ± 1.5 and nair=1 results in a reflection of 4%, which can also be achieved if the two indices are exchanged in the formula. The result is that another 4% of light is reflected by the interface between glass and air when exiting. As shown in Figure 1, a total of three interfaces can be found at an LCD behind a protective glass plate. They reflect 4% each, totaling 12% of the surrounding light. Two of the three reflections can largely be prevented by filling the interface between the glass cover and the LCD with an index-matched adhesive. Reflections of the surface of the glass cover can further be reduced by using anti-reflective layers.

CHALLENGING REQUIREMENTS

Industrial displays are often operated by a touch panel, which means that a second bonding task must be solved. For direct LCD bonding, the adhesive used must be extremely soft. Otherwise, disturbing image effects can occur—similar to the ring patterns caused when pressing a finger onto an LCD screen. Discolorations and shadows in the corners and alongside the edges, which are called mura effects, occur if a too-hard adhesive is used. The adhesive must have a Young’s modulus far below 1 MPa to prevent these disturbing effects. The combination of extreme softness and very high transparence, yellowing stability and good adhesion even after temperature and humidity storage was a special challenge in the development of a suitable adhesive.

In addition, the glass cover is often not entirely transparent; it includes printed structures that shadow off the bonding areas and limit the use of purely UV- or light-curing adhesives. Even if the adhesive is irradiated from the side, it will not fully cure in these shadowed areas due to the restricted light penetration depth. Consequently, the adhesive remains liquid and could leak later on.

A new patent-pending solution has been developed for this bonding task.** The new chemistry combines the required adhesive properties, including softness, high optical transparence, good adhesion and yellowing stability, with the availability of a second curing mechanism. Adhesive in shadowed areas reliably cures by reacting with the air humidity.

This process is slower than fast light curing, which lasts only seconds. Curing proceeds at a speed of about 2 mm per day, which is similar to conventional silicones. However, the crucial point is that fast processing is possible due to light curing with short cycle times, and shadowed areas reliably postcure afterwards. This mechanism works even if the air humidity is as low as 20%, which means that the components can postcure at room temperature and no further curing step is necessary.

**Developed by DELO Industrial Adhesives.

BONDING PROCESSES

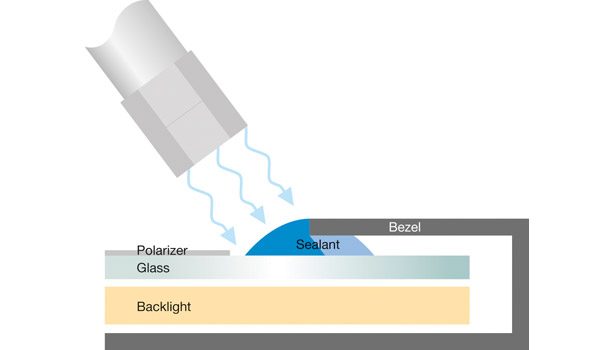

Two methods can be used in the bonding of industrial LCDs. The metal bezel around the display can be removed, and the glass cover can be bonded to the frameless LCD afterwards. If removal is not possible or intended, the gap between the display surface and metal bezel must be sealed with a special material before the low-viscous optically clear adhesive can be dispensed. Adhesive cannot flow into the display and damage the backlight. A bead of the high-viscous sealant is dispensed along the bezel and cured by light at the accessible areas (see Figure 2). The second curing mechanism ensures that adhesive flown into the gap is reliably humidity-cured.

The adhesive is also suitable for another process. A “dam” is dispensed onto the bezel and cured before dispensing the optically transparent adhesive (see Figure 3). The dam defines the layer thickness while tack prevents shifting of the glass cover that is laid on at the end of the process.

The optically transparent adhesive, called fill, is dispensed onto the display in a defined pattern that must be adapted to the display size and bezel height. Optimized dispensing parameters allow reproducible and bubble-free joining. Finally, the glass cover is attached either parallel to the LCD, or it is put down on one edge and then tilted down. As soon as the adhesive has spread, it can be cured. Adhesive in shadowed areas cures outside the production line by means of the second humidity curing mechanism.

YELLOWING RESISTANCE AND OPTICAL TRANSPARENCY

The key requirement of the adhesive is high transparency. The transmission of a 0.5 mm layer is more than 98% in the entire visible spectrum (see Figure 4). The yellowing stability was verified in accelerated sunlight tests.

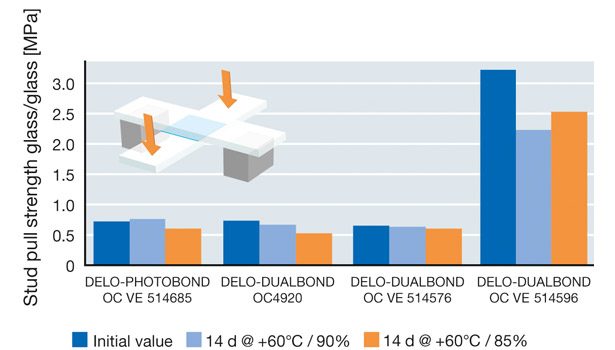

As the adhesive must be extremely soft, the adhesion values are rather low. Figure 5 shows typical adhesion values in the stud pull test. For this test, two elongated glass plates are bonded to form a cross of an area of 25 x 25 mm2. The plates are then pulled apart vertically to the bonding area. The resulting forces remain constant even after humidity storage and are sufficient for large-area bondings. For a 10.4 in. display, a stud pull force of 0.5 MPa results in a release force of more than 1,600 kg.

Typical refractive indices are around 1.47. This is very close to the values of glass (e.g., quartz glass with 1.46), and typical values of cellulose acetate (triacetate or TAC film) with 1.48. This is the material used as polarization film of the LCD, which is the actual surface to be bonded.

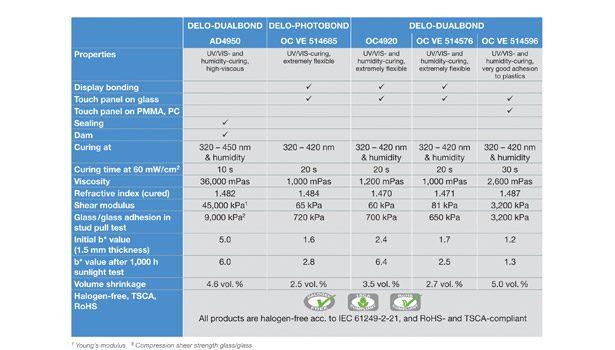

Table 1 shows typical parameters. The first adhesive is a high-viscous material to be used as sealing or dam. Three soft, optically clear adhesives for direct LCD bonding are also listed. The first one is purely light-curing, the second one is dual-curing, and the third one is a dual-curing product with further optimized yellowing resistance. The last adhesive on the right is somewhat harder. It gives improved adhesion to plastic and is suitable for bonding PMMA covers.

A BETTER DISPLAY

A completely new chemistry has been developed with the new adhesives: dual curing by light and humidity. Used in industrial displays and touch panels, the optically transparent, yellowing-resistant and soft materials are ideal for large-area display bonding.

For more information, contact DELO Industrial Adhesives at (978) 254-5275, info@delo.us or www.delo.us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!