Advancing Adhesives: Hot Melts Heat Up

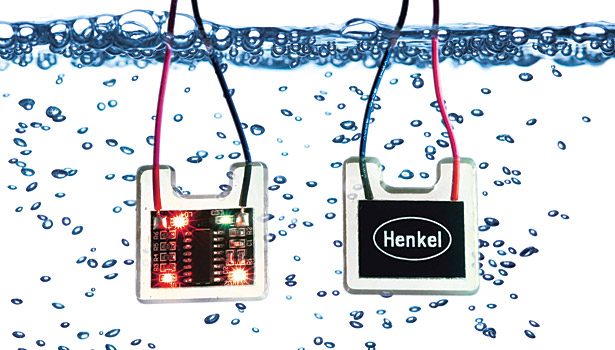

New hot-melt adhesives can resist both heat and water.

Henkel has introduced new molding products under the Macromelt brand for electrical applications. These products can reportedly offer reliable, resilient and resistant solutions for even the toughest conditions.

Henkel invented Macromelt molding; as a result, the company was responsible for the first case in which a cable assembly was encapsulation-molded in an engine compartment of an automobile—manufactured by Citroën of France—almost a quarter of a century ago.

Since that time, molding products have continually improved, with ongoing adaptation to the specific conditions prevailing in the user industries. In addition to performance, increasing importance is being attached to the sustainability of Henkel’s products; these new hot melts comprise up to 80% renewable raw materials.

FLAME RETARDANT AND SELF-EXTINGUISHING HOT MELTS

Macromelt Q 5361 is self-extinguishing and reportedly extremely flame resistant. Consequently, it has been assigned the best inflammability class, VO, qualifying it for many applications, including those where heat is a major factor. The hot melt extinguishes itself after a maximum of 10 seconds, with no burning drops and a maximum post-fire glow time of 30 seconds. Applications include the sealing of cable assemblies/harnesses in vehicles, and in solar and wind power generators.

Macromelt OM 671 is a new hot melt characterized by its extreme temperature tolerance. This hot-melt adhesive remains flexible even at -50°C, yet only softens at temperatures upward of 190°C. As it is not susceptible to cracking, the hot melt is suitable for the manufacture of large connectors such as those used in specialty vehicles—particularly those exposed to extreme temperature fluctuations. These could include winter service vehicles, agricultural machinery, municipal service vehicles and excavators.

Macromelt OM 653 is new and particularly hydrolysis-resistant (i.e., able to withstand water and moisture). Every polyamide tends to undergo irreversible mechanical degradation if it is exposed over lengthy periods to wet, humid environments. By contrast, OM 653 regains its original stability and tensile strength once the component has dried. It can thus be used at locations in the vehicle that are regularly exposed to wet conditions.

ENCAPSULATING RESINS

Henkel offers encapsulating resins for particularly tough specifications relating to temperature and media resistance. The latest development in the field of encapsulating compounds for optical applications, such as the sealing of luminants (LED arrays), is the highly transparent, two-component silicone Loctite SI 5700, which reportedly offers good adhesion on a range of substrates, such as metals and plastics.

Moreover, the material’s high transparency is essentially permanent, with none of the yellowing frequently encountered in other technologies under exposure to elevated temperatures or UV light. The molding produced with this material is free of bubbles, enabling the manufacture of optically unblemished, high-quality products. This newly developed silicone is particularly suitable for the protection and sealing of LEDs, such as in modern street lights, façade lighting fixtures, advertising signs, illuminated lettering, and other outdoor applications.

For more information, visit www.henkel.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!