Flame-Retardant Foam Gaskets: Fire Proof and High Performing

Flame-retardant foam gaskets play a significant role in preventing or delaying the spread of fire.

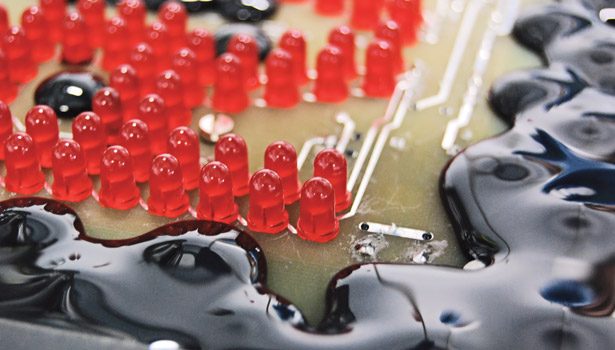

Polyurethane-, epoxy- and silicone-based reactive resins are used for a variety of products in the lighting industry. The applications range from the casting of sensors or ballasts and the sealing of the luminaire to the bonding of LED modules into a tube. The characteristics of the products for the respective application vary, depending both on the technology of the lamp (e.g., fluorescent or LED) and on its specific use.

Flame-retardant, UL-listed foam gaskets for the lighting industry play a significant role in preventing or delaying the spread of fire. At the same time, the sealing systems must meet the highest chemical and mechanical requirements, as well as environmental standards. This provides the developers of resins with major challenges, because the use of fire retardants can affect the performance of the sealing systems.

Incineration and Fire Retardants

Incineration is a sequence of physical and chemical processes. For the combustion process, three components are needed: heat, combustible material and oxygen. In this case, the plastic represents the combustible material. The process is divided into three steps.

• Step 1: By adding heat (ignition source), the plastic is initially softened and then, above a certain temperature, decomposed. Flammable gases (radicals, for example chain fragments or hydrogen radicals) are thereby generated. This step is called pyrolysis.

• Step 2: With the oxygen, the combustible gases form a mixture that ignites at a certain temperature, forming hydroxyl and oxygen radicals. In the further course of the combustion process, carbon monoxide is produced, which reacts further to form carbon dioxide.

• Step 3: In addition to the products of combustion, large amounts of heat are released. Some of this heat reaches the plastic surface again, whereby the combustion process is constantly renewed. This creates an ever-renewing process cycle, the so-called combustion cycle.

Flame retardants are additives that suppress or remove one or more components of the incineration process. This implies that a sufficient amount of flame retardant must develop its inhibitory effect at the right stage of the process.

For plastics, the number of requirements for flame retardants in addition to their flame retardancy is very high. They must be environmentally friendly and safe for humans, animals and plants, and must not release any additional toxic fumes in the case of fire. It must be guaranteed that flame retardants are not released from the finished product into the air or water. Furthermore, flame retardants are not to react with the resin or other components, thereby affecting the material in its functionality.

Shore Hardness and Bulk Density

The challenge in the development of flame-retardant foam gaskets is to maximize flame retardancy while maintaining the mechanical properties. Among others, flame retardants can cause a deterioration of the mechanical and electrical properties of the plastic; influence resistance to water, temperature, light, chemicals, etc.; and alter the processing behavior or the processing time window.

Maintaining the lowest possible Shore hardness and a low bulk density poses the biggest problem. The use of flame retardants causes a change in the properties of the integral skin of the foam. The ultimate goal is to develop fire-retardant foams, which, despite the changed properties through the flame retardant, achieve the necessary physical parameters required by the lighting industry, including:

• Compact, tear-resistant integral skin

• Low water absorption

• High sealing quality

• Fast demoldability

• Good adhesion to PVC

• Good flow properties

• Good resilience

Developing such a strong performing and flame-retardant material is only possible with experience and a lot of work in the laboratory. In addition, the application method also has a significant effect on the performance.

For more information, visit www.rampf-gruppe.de.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!