Adhesives at Work: Using Conductive Adhesives for Thermal Management in Micro- and Power Electronics

Thermally conductive adhesives are a proven yet underutilized bonding solution in electronics engineering.

The increase in demand for mobile electronic devices has brought about new design challenges with an ever-greater emphasis on mechanical strength and thermal management capability. As substrate sizes shrink and operating environments become more rugged, integrated product design must overcome the challenge of dissipating heat while maintaining shock resistance.1 Conductive adhesives are a proven yet underutilized bonding solution in electronics engineering.

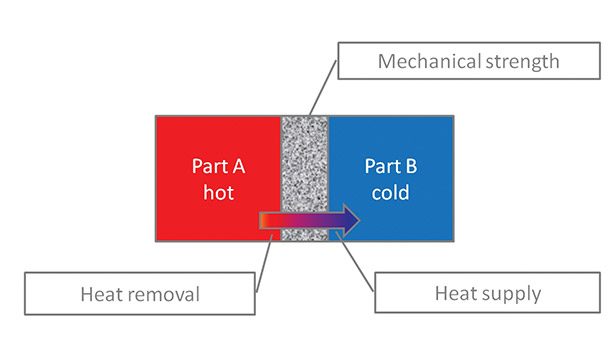

Figure 1 illustrates thermally conductive adhesives joining two components to transfer heat from the hotter surface to the colder one. Adhesives can cover large surface areas, thereby providing the necessary heat transfer and forming a durable structural joint. In contrast, most other thermal interface materials (TIM) like thermal greases, phase-change materials or polymer pads require mechanical fastening. One exception, soldering, offers mechanical stability but at higher processing temperatures than an adhesive solution.

Traditional thermally conductive adhesives and potting applications include: mounting of heat sinks in microelectronics, die bonding, encapsulation, and sensor potting. Moreover, there is a growing demand in non-traditional applications such as power electronics, electrical and power engineering, LED lamps, solar energy devices, heat exchangers, and automotive components. The products represented by this wide range of applications have unique requirements and often challenging processing parameters, in addition to disparate mechanical properties. Here adhesives can bridge the thermal mismatch between distinct components.

Composition and Properties

Thermally conductive adhesives are often composed of single- or two-component epoxies, alongside other systems like silicones. The advantages of epoxies are thermal, chemical and structural stability. Generally, epoxies (like polymers) have a poor intrinsic thermal conductivity of 0.2-0.3 W/mK. When these epoxies are filled with ceramic or metallic powders like alumina, boron nitride, aluminum or copper, heat transfer increases substantially. The bulk thermal conductivity of these particles ranges between 30 and > 300 W/mK.2

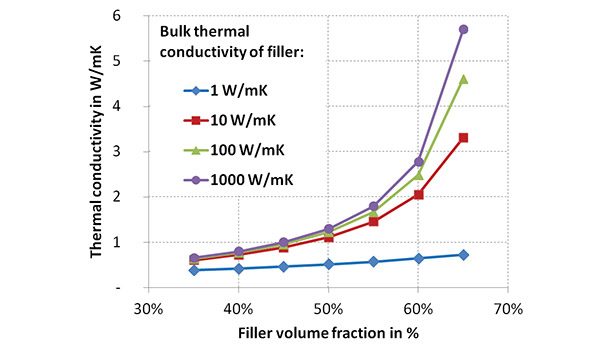

Applying a simple mixing rule, one might conclude that blending of 50% epoxy and 50% thermal filler will result in a composite featuring an average thermal conductivity, but unfortunately this is not the case. Moreover, thermal conductivity doesn’t depend as much on the conductivity of the filler, but rather the relative ratio of the filler to the epoxy.3 There has been lot of research about the composite thermal conductivity of filled polymers. A well-acknowledged model is the equation found by Lewis and Nielsen:4

where λC is the thermal conductivity of the composite, λM is the thermal conductivity of the matrix, and the right part of the equation consists of various parameters where fis the volume fraction of the filler. The parameters A, B, and ctake account of the particle form, the thermal conductivity, and the maximum possible packing density of the filler.

Data generated using this equation show that the volume fraction of the filler should be 50% or more just to achieve a thermal conductivity of above 1 W/mK (see Figure 2). Even more significant is that similar levels of thermal conductivity occur regardless if the filler has a 10, 100 or 1,000 W/mK, respectively.

Considering these properties, the goal to maximize thermal conductivity therefore requires a high ratio of filler content. However, a high ratio of abrasive particles reduces reasonable flow properties that will be needed to mix and apply the adhesive. Further, mechanical strength may suffer as filler displaces epoxy. As a consequence, any product development team will have to find a compromise between thermal conductivity and processing parameters.

Commercially available thermally conductive epoxies feature conductivities ranging from < 1-1.5 W/mK if electrically insulating, and up to 2-3 W/mK when filled with metal powders. Big discrepancies in manufacturer specifications can result from non-standardized parameters like bond line thickness, curing temperature and duration, and interface conditions, as well as the measurement principle itself. This must be considered when developing new products. Another well-known discrepancy lies between the specified bulk thermal conductivity and the real thermal resistance the material will show in a given assembly.

Application Examples

In microelectronic assemblies, thermally conductive adhesives are an established means of joining and protecting components, such as die attach, underfill, encapsulation and heat sinking. The application of thermally stable epoxy-based resins enables the processing of temperature-sensitive parts, so they can withstand reflow soldering and improve operational stability.

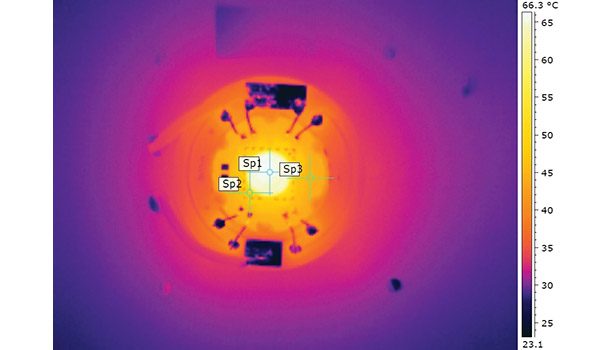

A growing application trend is the mounting of LED chips on heat sinks (see Figure 3). Current power LEDs are consuming > 500 mW per unit, where only 20% of the energy is converted to visible light. A larger portion of the energy has to be radiated or dissipated to keep the component temperature below 120°C. At higher temperatures, both the light yield and the service lifetime of the lamp will decrease.

When mounting LED chips to a heat sink, thermal conductive adhesives excel because they provide both mechanical and thermal bonding over the whole area. Thus, the heat dissipates very efficiently. Figure 4 shows a thermal image of a power LED mounted on a heat sink by using a thermally conductive adhesive during operation. The maximum temperature is about 66°C. Each 1°C incremental increase in operating temperature would reduce the lifetime of the LED significantly.

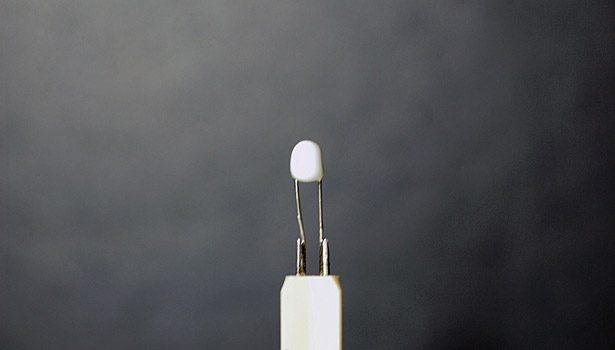

Another application is the potting or sealing of temperature sensors in electronics (see Figure 5). The thermally conductive adhesive acts as an effective encapsulant from moisture and enables a good heat transfer between the sensor and the environment.

Recently, demand has begun increasing for innovative manufacturing concepts for electric and hybrid vehicle batteries, motors, and fuel cells. This demand can partially be addressed through the use of thermally conductive adhesives.5 Examples including the joining and potting of traction batteries, assembly and coil potting of electric motors, mounting of heating and cooling piping, etc.

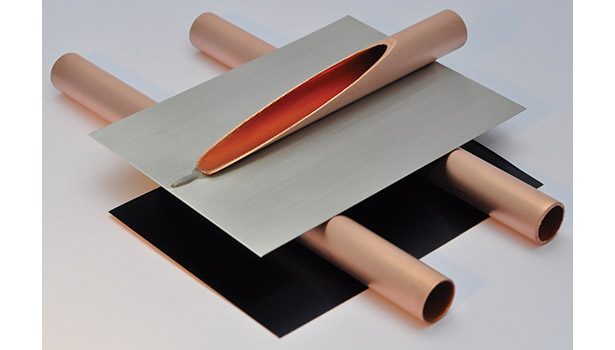

Similarly, applications exist for components and assemblies in general power engineering, including solar thermal devices or heat exchangers. Figure 6 shows a copper tube that is glued to an aluminum panel using a highly thermally conductive adhesive. Adhesives enable force-fitted and thermally conductive joints found in traditional soldering and welding, but avoid high thermal loads during processing and the subsequent distortions or discolorations. Moreover, joining of difficult material combinations like copper and aluminum is possible without restrictions.

Next-Generation Thermally Conductive Adhesives

When considering future application requirements, thermally conductive adhesives are fairly flexible. Based on the previously mentioned relationship between conductivity and filler loading, systematic testing is done to create a new series of improved adhesives and pottants. After an appropriate filler type has been selected, several design parameters (e.g., viscosity and rheological properties of the resin matrix, filler load, grain size, aspect ratio, size distribution, and surface properties of the filler particles) can be manipulated in order to optimize the result. Correctly selected additives will enhance the performance of the composites. Lastly, the desired adhesion properties, mechanical specifications (including strength) and service durability need to be addressed.

Prior investigations have resulted in adhesives with thermal conductivities of 2-3 W/mK that also maintain full electrical insulation. In the case of metallic fillers where dielectric strength is not explicitly required, even higher thermal conductivities of > 5 W/mK can be achieved. Despite manufacturer claims to have reached even much higher conductivities, it is important to proceed with caution and critically examine data sheet specifications with respect to the measurement ambiguities previously mentioned. A wide range of testing methods can be used to determine thermal parameters, and it is therefore important to confirm that marketable data from a convenient testing method satisfies real-world requirements in the application. Testing of commercially available products has revealed great differences between stated and observed values.

Regardless of the thermal properties, all adhesives are packed and processed with regard to their respective type. Room- and heat-cured two-component versions are available in separate containers, in dual cartridges with a static mixer, or pre-mixed and frozen and packaged in syringes. Frozen pre-mixed dual components are ready for use after thawing and must be handled with care to prevent air bubbles from forming. Single-component versions are even easier to process, as they don’t need to be metered or mixed and can be stored in a refrigerator and stirred before use.

Improvements in thermally conductive adhesives make adhesive bonding an increasingly attractive alternative to welding, soldering and mechanical joining in specific applications. Regardless of the application, good thermal management improves durability of the end product and hence positively affects its energy efficiency and eco-friendliness.

For more information, contact the author at a.maurer@polytec-pt.de or visit www.polytec-pt.com.

Author’s Acknowledgements

The mentioned investigations are supported by the German Federal Ministry for Economic Affairs and Energy through the Central Innovation Program SME (Zentrales Innovationsprogramm Mittelstand – ZIM). With special thanks to all4-GP North America Inc. and Mark Goscenski.

Footnotes

1. Moore, A.L., Shi, L., “Emerging Challenges and Materials for Thermal Management of Electronics,” Materials Today, 17, 4 (2014), 163–174.

2. Petrie, E.M., Epoxy Adhesive Formulations, McGraw-Hill, New York (2006), 171–182.

3. Bigg, D.M., “Thermal Conductivity of Heterophase Polymer Compositions,” Adv. Polymer Sci., 119 (1995), 2–39.

4. Nielsen, L., “Thermal Conductivity of Particulate-Filled Polymers,” Appl. Polymer Sci., 17 (1973), 3819.

5. Maurer, A., “Adhesives with High Thermal Conductivity and Reliability for Power Engineering and E-mobility,” European Coatings Congress, Nuremberg, April 2015 (accepted).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!