Focus On

The Right Packaging for Finished Adhesives

How one adhesives manufacturer is practicing sustainable management in packaging applications.

Industrial adhesives manufacturer DELO has long gone its own way in terms of optimized and sustainable packaging and shipping of adhesives. Thanks to its packaging and logistics concept, which is being constantly revised, the company was awarded second place in the Responsible Care Competition held by the German Chemical Industry Association (VCI).

DELO mainly develops products for electronic and automotive applications, in which only small amounts of adhesive are needed; that adhesive, however, must meet stringent requirements. Because so little of it is needed in these applications, the adhesives are generally filled in small, plastic containers such as cartridges made of PP or PE that have graduated capacities ranging from 5 ml to 1 l and bottles from 50 ml to 1 l. Hobbocks are used for quantities of up to 30 l. Designed in plastic or metal, they are often coated on the inside or contain inliners.

These adhesives are produced exclusively at the company’s headquarters in Germany. The quantities are easily managed, compared to those of flooring and wallpaper adhesives. Transportation within Europe generally takes place by land and, occasionally by air freight, as is the case for shipments to the U.S., Asia, and the rest of the world.

Employees from different departments, including logistics, product management, customer quality support, engineering, and internal sales, are in charge of the logistics concept. Several years ago, a few employees set up this logistics team themselves. They meet regularly to discuss how to improve delivery sustainability and efficiency, as well as maintain a high level of safety. Sustainable logistics can only be achieved by many little steps of continuous improvement in terms of environment and safety.

Space in the Box

One major improvement DELO has made is its new packaging design, which uses optimized cardboard box sizes. Growth in adhesive sales over the past several years has made this change possible, as made-to-measure cardboard boxes require a certain minimum quantity to ensure economic efficiency. Adjusting the sizes of cardboard boxes is more complicated than it may seem at first glance, since many bulk purchasers have specified the box dimensions and any modification has to be approved by the customer.

An example of such an adjustment is the packaging for the frequently used 20-oz (600-g) cartridges. For some time, only 13 of these cartridges have been packed into a cardboard box, instead of the customary 30 cartridges. This has reduced the weight from 18-24 kg to 8-12 kg and led to improved workplace safety. The layouts of the inserts for containers have also been optimized, making enough space for almost a third more cartridges.

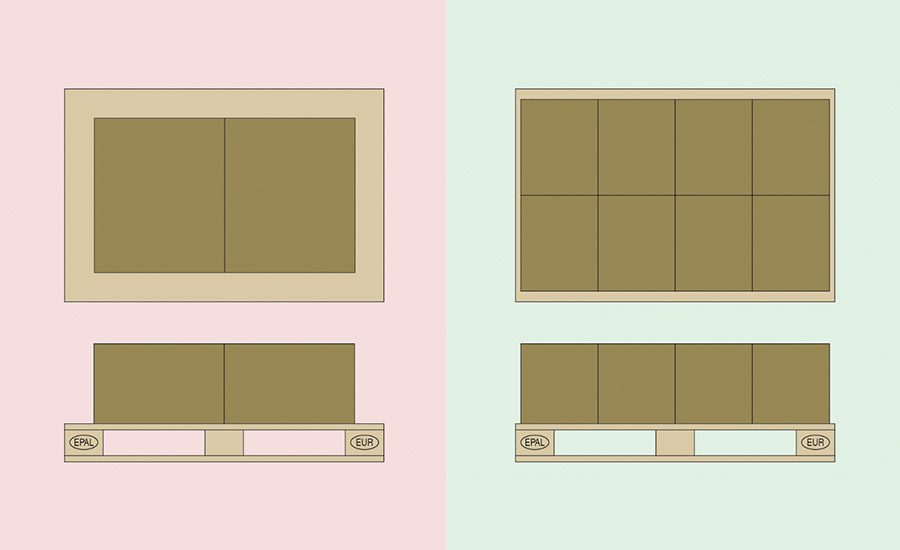

The cardboard boxes can now make better use of a Euro pallet’s surface area, thus further reducing transport volume and storage space. Instead of 60 cartridges, there is now space for 104 cartridges on one layer, which improves space usage significantly.

As is standard practice, empty spaces in packaging boxes for adhesives need to be filled with cushioning material. DELO reuses clean packaging material as much as possible. In addition, the bubble wrap used is recyclable and inflated at the DELO plant, which saves transportation and storage space.

Some attempts were made to replace Styrofoam chips with cornstarch-based, biodegradable products. However, once flattened, the chips DELO tested remained flat and left lint residues. The chips also stuck to the containers when they came in contact with moisture. These factors made DELO refrain from using chips made from natural ingredients.

Given the importance of transport safety in sustainable logistics, DELO has been using cardboard edge protection products for goods transported on pallets. The edge protection prevents palletized goods from being damaged by the retaining straps, a move that DELO believes shows that even small steps are important in terms of environment and safety.

Keeping Products Cool

DELO offers a range of products, all of them solvent-free reactive adhesives that make labeling easier compared to dispersion adhesives. However, since they need to be stored at different temperatures, seven temperature ranges exist. In addition, it is necessary to differentiate between hazardous and non-hazardous goods, which results in 14 transport classes. For the most temperature-sensitive products, a temperature of -40°C must not be exceeded during transportation.

Two methods are applied for cooling adhesives in Styrofoam boxes: thermal packs containing eutectic gel or dry ice. The special properties of thermal packs with eutectic gel enable a longer, uninterrupted cold chain than what can be provided by water-based cold packs having the same volume and weight. The use of such eutectic packs is advisable when a constant cooling temperature must be ensured during transportation. DELO tries not to use dry ice since its carbon footprint is higher and the hazardous material regulations are complex.

A cold chain logger used passively, for the most part, ensures that the cooling concept works by recording and monitoring the temperature during the entire transportation process. The logger triggers a warning in case of heat exposure.

The Journey is the Destination

Designed as a bottom-up approach and following a concept of continuous improvement, the logistics team is continuously developing new and more sustainable shipping processes. Such projects generally focus on long-term achievements, since results cannot be measured until later in the process. What counts is that every step, as small as it may seem, contributes to future progress. The success of such small actions is revealed by the fact that DELO’s sales and output have increased by 80% during the past four years, while transportation has only increased by 11% within the same period. ASI

For more information, visit www.delo.us.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!