Meeting Modern Challenges in Bonding to Automotive Thermoplastic Olefin Plastics

Thermoplastic olefin plastics present unique challenges for pressure-sensitive adhesives in automotive applications.

Thermoplastic olefin (TPO) materials belong to the larger group of thermoplastic elastomers (TPEs). As such, they come in many formulations and can be molded into parts with different surface finishes. Increasingly used in the automotive industry as an alternative to high-cost, heavy metal materials, TPO plastics present unique bonding challenges for pressure-sensitive adhesive (PSA) manufacturers.

TPOs fall into the category of low-surface-energy (LSE) materials. Pressure-sensitive materials generally have a lower affinity for LSE surfaces than, for example, materials like stainless steel or glass. Over time, oils present in the TPO may migrate to the surface and interfere with the adhesive bond. TPOs are selected by auto manufacturers in part due to their resistance to elements such as chemicals, UV, high/low temperatures, and oils that a vehicle will be exposed to over the course of its service. In addition, TPOs are impact resistant and highly moldable to create the shapes and custom pieces needed for today’s automotive interior designs. Adhesives must be formulated to not only bond to this challenging material, but also to withstand the same operating conditions as the TPO.

Now consider that PSA manufacturers must not only bond to the TPO substrate, but also join a material such as a foam, vinyl, or other LSE material to the TPO, increasing the bonding challenge. Further complicating the development of new PSAs is the increasing demand for low-volatile organic compound (VOC) adhesives that comply with Japan Automobile Manufacturers Association (JAMA) standards. PSA manufacturers must address all of these issues when developing bonding solutions for the automotive industry and do so using a combination of adhesive formulation development, adjusting the caliper or thickness of the adhesive, or with a combination of the two.

Adhesive Development

Understanding all of the “failure modes” is critical for the PSA provider so that the most cost-effective bonding solution can be offered. In the world of PSA chemistry, compromises are inevitable. For example, the nature of PSA chemistry is such that it is difficult to offer both high- and low-temperature resistance in one adhesive. In addition, the need for UV, chemical, and/or solvent resistance leans toward acrylic adhesive chemistry, yet adhesion to LSE substrates like TPOs is better achieved using rubber-based adhesive chemistry.

Additional material-specific performance requirements come into play, especially when TPOs are involved. For example, what grade of TPO is being used and is it extended with oils? What about the other surface? Plasticizer resistance? Low fogging and, more recently, low VOC? The surface conditions of some molded TPO parts and some foam materials may warrant the use of heavier caliper adhesive systems.

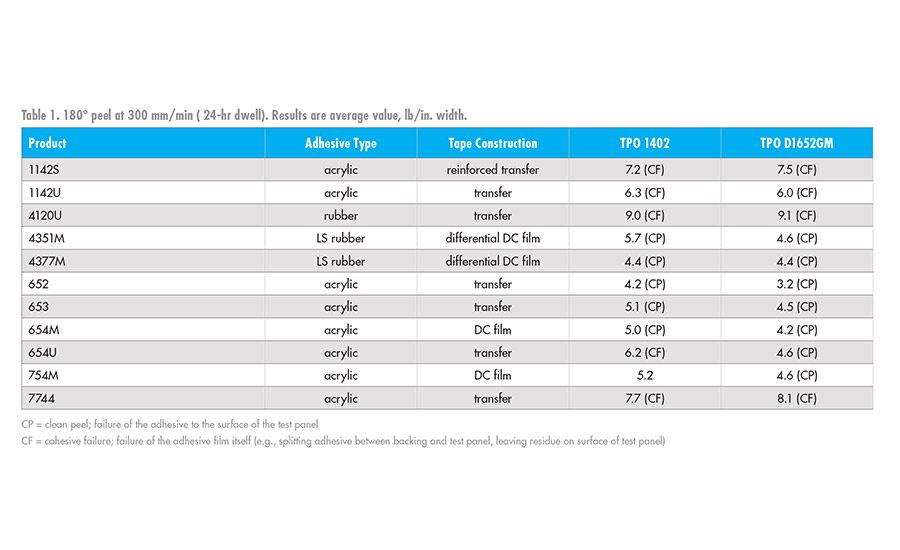

Table 1 provides acrylic, solvent rubber, and hot-melt rubber adhesive chemistries, as well as a variety of common tape constructions that reflect the wide array of possible customer considerations to meet specific requirements. It is evident that significant variation in the peel adhesion values is achieved from one adhesive type to the next, as well as variation in the same adhesive system applied to different TPO substrates. Testing is a critical part of the development process, including bonding studies to a customer’s TPO material and to foam and non-foam substrates.

Understanding Tape Design

As depicted in Table 1, both adhesive chemistry and tape construction play a role in determining the best bonding solution for the TPO component. Because PSA materials are converted, offering several constructions provides the PSA tape converter maximum latitude in its processing operations.

Double-coated tapes with PET carriers permit parts to be die-cut into complex shapes and still maintain dimensional integrity. On the other hand, if a flexible gasket must conform to a part with a complex shape, a double-coated tape with a tissue carrier or an unsupported transfer tape might be required. Double-coated foam tapes are employed for special applications such as mounting an automotive antenna base to the glass backlight or rear window.

Adhesive chemistry is equally critical to the success of a TPO bonding system. Adhesive systems are constantly evolving to meet the demands of not only the newest engineered plastics, but also to constant changes in foams and other substrate materials. Both acrylic and rubber-based chemistries can be employed, depending on the end use requirements. Acrylic-based systems typically have better UV, chemical, and solvent resistance, but rubber-based systems offer more aggressive bonding characteristics and present better economies, in most cases.

Even the paper or film release liner requires careful consideration. Kiss-cutting operations may require the use of heavy paper board liners, whereas high-speed rotary die cutting can demand the use of poly-coated or film liners. The desire to recycle the discarded liner may also enter into the selection process. The ability of the adhesive tape to release properly from the liner requires special engineering, especially with LSE materials like TPOs that typically require the use of more aggressive adhesive systems, further complicating the release liner issue. PSA tape manufacturers sometimes devote more development resources to the engineering of the release liner—which is ultimately discarded—than to the adhesive itself. Clearly, without an effective release liner, even the best adhesive system is rendered useless.

Managing VOCs

For the last decade, a greater emphasis on reducing VOC content in materials has added a further challenge for PSA manufacturers. VOCs are organic compounds that vaporize and enter the atmosphere under normal, everyday conditions. The Japanese Ministry of Health, Labour, and Welfare (MHLW) issued exposure guidelines in 2002 limiting the detectable limits for 13 VOCs found in confined areas such as homes and auto interiors. The automobile industry has largely adopted these standards, and testing for VOC content has now become part of the standard protocol for PSAs used in automotive bonding applications.

However, in the U.S., confusion exists in the world of PSAs since no national or worldwide standards have been established. PSAs can be called “low odor” or “low VOC” without reference to any guidelines.

Having an extremely low-VOC adhesive is clearly only half the battle. Extensive testing must confirm that the PSA also meets the requirements of cohesive strength, temperature resistance, chemical and UV resistance, and other factors deemed critical by the end user. The adhesive referenced in Table 2 shows exceptional bonding characteristics to a variety of TPO materials, excellent high/low temperature performance, and significant resistance to chemical and UV exposure.

High-Performance Agility

The use of TPO materials continues to expand in the automotive and related industries. PSA manufacturers must remain agile in developing adhesive systems that can not only meet high performance demands with a wide variety of TPO materials, but also perform in stressful operating conditions.

Combined with greater emphasis on low VOCs, “green” materials, lightweighting of vehicles, and overall cost reduction, the challenge is significant. PSA manufacturers have the opportunity to be a developmental partner with molders, TPO suppliers, and automotive OEMs in developing new solutions for the next generation of automobiles.

For more information, call (631) 727-6000, email rinyinfo@berryglobal.com, or visit www.adchem.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!