What Are Pressure-Sensitive Adhesives and Tapes?

A variety of adhesive chemistries and tape formats can be combined to help ensure that a specific tape satisfies a specific need.

The Pressure Sensitive Tape Council defines a pressure-sensitive adhesive (PSA) as requiring two things: aggressive and permanent tack, and adhesion with finger pressure. This simple definition makes the concept of a PSA easy for anyone to understand. It also leaves room for differentiation: a variety of adhesive chemistries and tape formats can be combined to help ensure that a specific tape satisfies a specific need.

While a couple of types of tape can cover most general household needs, production on an industrial scale requires tapes with specific properties so that each assembly performs predictably and is the same as all the others. Important considerations involve both the type of adhesive, designated by its main chemical component, and the format of the tape.

Adhesive Chemistries

Common adhesive chemistries used to produce tapes include rubber, acrylic, and silicone. Rubber can be either naturally derived from certain plants of the genus Hevea or made from synthetic materials. Both types of materials can be tackified to make the adhesive stickier.

Rubber-based tapes feature very high tack, which enables them to stick immediately on contact with the substrate. These relatively low-cost solutions are also cleanly removable from many substrates for applications that may need to be changed periodically (e.g., floor and safety marking).

Their lower resistance to environmental conditions such as ultraviolet (UV) light or temperature means that rubber tapes may not be suitable for outdoor applications or assemblies that go through a heat treatment process, such as medical sterilization or painting. In addition, rubber-based adhesives are unable to bond low-surface-energy (LSE) substrates, including many popular plastics.

Acrylic tapes are the workhorse of industrial bonding and are found in nearly every industry. Acrylic adhesives tend to be naturally tacky and were originally developed for PSAs because natural rubber tends to yellow and degrade when exposed to UV light.

Acrylic chemistry is an ever-changing field that enables formulations to be engineered specifically to provide high- or low-temperature performance, adhesion to LSE materials, varying thickness, and even unique properties such as flame retardancy. While chemically similar to acrylic liquid adhesives, acrylic tapes are fully cured and do not require any additional chemical reaction or cure time. The bond is created by using primarily mechanical interlocking, in addition to some Van der Waals interactions and hydrogen bonding at the interface.

Acrylics have the ability to bond the widest variety of materials, so fewer types of tapes need to be purchased and stored. Acrylic tapes are available in myriad formats and provide the broadest mechanical performance capabilities, from removable tapes to aggressive, high-strength industrial-grade bonding.

Acrylics require relatively clean surfaces for reliable performance, so taking the time to properly prepare the surface can be important to the final bond. In addition, their temperature resistance is not as high as that of silicones, though very high-temperature acrylic PSAs are available.

Silicone tapes are best known for tolerating an extremely wide temperature range, from -40°F (-40°C) to over 500°F (260°C). Silicone adhesives are themselves LSE materials. This means that they bond well not only to other silicones, but also to surfaces such as oil-resistant coatings and fluorinated materials that have very low surface energy.

As more electronics are made resistant to the light oils found in fingerprints, more silicone-based tapes are used to bond those materials. Because the backbone of silicone chemistry is inorganic (not based on carbon chains), these adhesives are inherently hypoallergenic and relatively resistant to mold growth. However, silicones have relatively low strength and are unable to bond to porous materials such as wood or cement.

Tape Formats

In addition to the adhesive chemistry, it is important to tailor the tape construction to meet the specific needs of industrial applications. Widely used formats include adhesive transfer tape, double-coated tapes, and single-sided tapes.

Adhesive transfer tape (ATT) comprises a layer of PSA with a release liner, which enables the tape to be handled. When the liner is removed, only the adhesive remains. ATTs are essentially similar to a glue, with the benefit of no drying or curing time. They are used in the same way as double-coated tapes, except the adhesive is always the same on both sides.

Double-coated tapes feature a carrier layer with a PSA on each side. Using the same or different adhesives allows the tape to adhere to similar or completely different substrates on each side. A double-coated foam tape features a foam carrier between the adhesive layers to provide gap-filling or cushioning properties.

Double-sided tapes can help smooth out production runs. The first substrate can be taped and the liner left in place until it is time to bond the second substrate; the assembly can even be shipped elsewhere. The second adhesive is then exposed by simply peeling the liner when it is time to attach the second substrate.

In addition to their ubiquitous industrial use for cartons and packaging, single-sided tapes can serve to bundle wires together and keep them out of the way (e.g., in vehicles or appliances). These tapes are also used for seaming sheets of material together and as tabs to start or finish rolls of materials.

Conversion

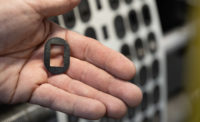

Many industrial applications require tapes in precise shapes to bond parts or layers together. The tape manufacturing process enables nearly every chemistry and construction to be created in rolls or sheets that can then be slit or die-cut by a converter as needed. In addition to their own expertise at converting, these companies often have experts who can help address manufacturing concerns related to the tapes under consideration for specific applications.

The PSA Advantage

Tapes really are simple, both to understand and to use. Welding requires extensive training and only works with certain materials, mechanical fasteners can be labor intensive, and liquid adhesives require precise amounts and mix ratios and an awareness of the time required to cure before moving to the next step. Everyone has used a tape at some point in their life, so the training required for the labor force is minimal.

Uniform construction also makes tapes relatively easy to automate. Mechanical processes can be used to start the tape, a roller can apply uniform pressure, and a blade can cut the tape. It is also possible to automate the liner removal, if desired. In fact, extended liner tapes have a liner that’s wider than the adhesive so the edge is easier for either a machine or a human hand to initiate removal. With all of these advantages, as well as the flexibility provided through the various adhesive chemistries and tape formats, it’s time to start looking at where tape can fit into your assemblies and processes.

For additional information, visit www.3m.com/bondingandassembly.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!