Home » adhesives in assembly

Articles Tagged with ''adhesives in assembly''

Adhesives offer significant advancements in electric vehicle safety, cost, durability, and performance.

Read More

Ask Dr. Dave

Adhesives for Fiberglass Bonding

What are the best adhesives for bonding fiberglass components?

July 20, 2021

HENKEL: Primerless Adhesive for Work Truck and Manufacturing Applications

The primerless adhesive is suitable for a variety of work truck and manufacturing applications that require high-strength adhesion of loads to thin walls or small areas.

July 6, 2021

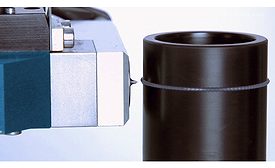

Common Dispensing Challenges and Solutions for Adhesives and Other Materials

Nearly 900 plant engineering and management personnel from diverse industries within the U.S. weigh in on specific challenges they face relating to their dispensing methods.

May 25, 2021

Modernizing Assembly Lines with UV LED Curing

Adhesive bonding, sealing, and coating processes in factory assembly lines are rapidly upgrading to UV LED curing technology.

May 12, 2021

DuPont to Build New Adhesives Manufacturing Facility in China

Products manufactured at the facility will serve customers in the transportation industry, primarily vehicle electrification applications and lightweighting.

April 26, 2021

From the Editor

Exploring Assembly Applications for Adhesives and Sealants

From automotive and construction to general industrial applications, the use of adhesives and sealants is expanding in assembly operations around the world.

April 23, 2021

Ask Dr. Dave

Superglues vs. Polyurethane Glues

Should I use superglue or one of the new polyurethane glues for general-purpose assembly and home repairs?

April 19, 2021

An Ounce of Prevention Leads to Efficient Adhesive Assembly Operations

Environmentally friendly cleaning and preventative maintenance can pay dividends in terms of efficient operation and a safer manufacturing environment.

April 12, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing