Home » dispensing

Articles Tagged with ''dispensing''

Senftl to Leave ViscoTec at End of 2021

Franz Kamhuber, Senftl's successor as managing director in the commercial area, and Martin Stadler, managing director for technology, will together lead the company going forward.

December 29, 2021

Nordson to Demonstrate Semiconductor Packaging Solutions at SEMICON Taiwan 2021

SEMICON Taiwan 2021 will take place December 28-30 in Taipei.

December 20, 2021

Product Profile

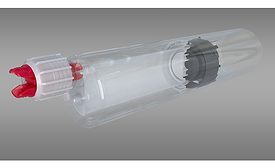

New Coaxial Cartridges Provide High Performance

Packaging and dispensing systems can help adhesive manufacturers easily and reliably pack their formulations while minimizing waste and allowing end users to efficiently apply the products.

December 13, 2021

Nordson Demonstrates Solutions for SMT Technology and Electronics Manufacturing at NEPCON ASIA 2021

The company featured technologies and products from the Nordson Electronics Solutions and Nordson Test & Inspection divisions.

November 12, 2021

3M Announces Bonding Process Center Evolution

Formerly known as Global Adhesives Solutions Labs, 3M Bonding Process Centers connect customers with local 3M experts to help solve problems and optimize processes.

September 24, 2021

VISCOTEC: Material Treatment and Supplying System for Automated Potting Applications

ViscoTec reports that ViScaFeed is suitable for abrasive, filled, or shear-sensitive fluids and pastes, regardless of their viscosities.

August 5, 2021

VISCOTEC: Two-Component Dispensing System for Potting Applications

The system is suited for low- to mid-viscosity, respectively self-leveling materials, like epoxies, polyurethanes, or silicones.

June 15, 2021

DELO AND INFOTECH: 3D Printing System

According to DELO, the system is suitable for prototype development and small-series production.

June 8, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing