Home » dispensing

Articles Tagged with ''dispensing''

From the Editor

What are the most prevalent challenges experienced by manufacturing companies in their dispensing operations?

Read More

Common Dispensing Challenges and Solutions for Adhesives and Other Materials

Nearly 900 plant engineering and management personnel from diverse industries within the U.S. weigh in on specific challenges they face relating to their dispensing methods.

May 25, 2021

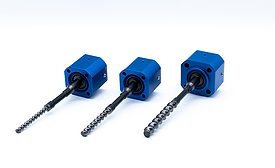

GRACO INC.: Two-Component Dispense Valve

It reportedly provides uniform and consistent blending of difficult-to-dispense materials for various applications.

April 22, 2021

ViscoTec Asia Celebrates 10th Anniversary

The company opened a representative office in Vietnam in 2018 and plans two more sales offices outside Singapore and Vietnam in the next two to three years.

February 8, 2021

Automating Medical Device Assembly

Medical device manufacturers can find success when they embed processes and systems in a holistic manufacturing concept that takes into account the entire value chain.

January 18, 2021

Bonding Natural Baby Product Materials with Hot-Melt Adhesives

Accuracy and high performance are critical when bonding natural materials to form disposable absorbent hygiene products such as diapers.

January 8, 2021

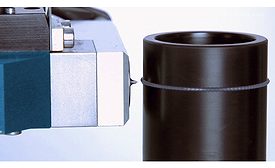

VISCOTEC: Diamond-Coated Dispensing Rotor

Rotors refined with a so-called “diamond coating” (DC) can reportedly double or triple the lifetime of the system until the rotor must be replaced.

October 8, 2020

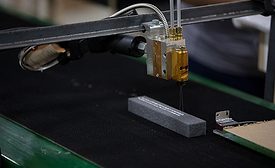

DISPENSE WORKS INC.: Bottle Filling and Robotic Assembly Dispensing System

An embedded dual memory processor with CF card reportedly requires no PC for operation and provides all preprogrammed software functions for filling, assembly, positioning, etc.

June 11, 2020

Case Study

Benefits of Potting Electronics in a Vacuum

Vacuum potting is mainly aimed at electronic components with small openings and complex internal structures.

June 10, 2020

Case Study

Leveraging Adhesive Technology to Support Healthcare Workers

Chicago Glue recently helped Systematics more than double its output of face shields for healthcare workers on the front lines of the coronavirus pandemic.

May 22, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing