Home » waterborne adhesives

Articles Tagged with ''waterborne adhesives''

Sustainability Practices in Pressure-Sensitive Adhesive Manufacturing

While challenges remain, the benefits of sustainable practices make a compelling case for the transition toward more eco-friendly adhesive manufacturing.

September 17, 2024

Formulating with Flexibility

Finding solutions to meet ever-evolving demands encourages flexibility and collaboration with suppliers, formulators and customers.

October 30, 2023

Arkema Discusses Integrated PSA Offering

Tim Pione outlines Arkema’s position in pressure-sensitive adhesives and what the company has planned for the future.

July 11, 2023

Applied Adhesives Acquires Premier Packaging Solutions

Based in Chattanooga, Tenn., Premier Packaging Solutions is a distributor of hot-melt and water-based adhesives.

November 3, 2020

Strategic Solutions

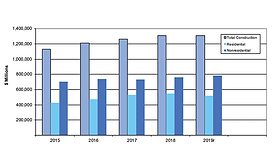

Market Dynamics for North American Sealants

Through 2019, the building and construction market was a sealants volume leader, followed by assembly operations and transportation.

August 17, 2020

Evonik Receives 2020 Ringier Coating Technology Innovation Award

Evonik reports that VP Disp. WF 7620, the newest rheology control dispersion in its Coatings Additives portfolio, was specifically developed to control the rheological properties of waterborne coatings.

July 21, 2020

Strategic Solutions

Formulation and Availability of Building and Construction Adhesives, Sealants, and Other Materials

Engineers, architects, specifiers, facility managers, and homeowners must spend time analyzing what performance levels can be obtained by the adhesive and sealant products that are available to them for the environments in which they are being used.

May 15, 2020

Strategic Solutions

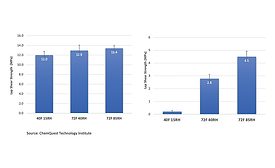

Third-Party Validation of Adhesive Performance

This second installment of a two-part series higlights the value proposition of independent material testing and validation to high-value end-use markets.

March 27, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing