ARTICLES

While challenges remain, the benefits of sustainable practices make a compelling case for the transition toward more eco-friendly adhesive manufacturing.

Read More

Trends in Reusable Protective Packaging Drive Growth of Pressure-Sensitive Adhesive Applications

Choosing the right pressure-sensitive adhesive (PSA) tape for reusable protective packaging depends on the need of the specific application and the materials that are being bonded together.

November 10, 2020

Focus On

Vertically Integrate for Sustainability

Vertically integrated tape suppliers can offer stabilized value, flexibility in product development and superior product performance.

November 13, 2018

The Greener Side of Adhesive Coating

A 100% solids adhesive coating process is operationally and environmentally sustainable for pressure-sensitive adhesive construction.

May 4, 2017

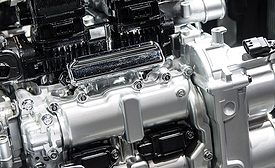

Pressure-Sensitive Adhesives Are in the Driver's Seat

Industrial PSA tapes with high temperature resistance bring new value to production assembly in automotive and transportation markets.

July 1, 2016

Clean and Green PSAs

Pressure-sensitive adhesives offer the benefit of having low to no VOCs.

November 1, 2015

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing