End User Features

Recovering end markets are contributing to increased merger and acquisition activity in adhesives and sealants activity.

Read More

Vacuum Dispensing Helps Users Say Goodbye to Air Bubbles

Vacuum dispensing prevents air from getting caught between a component and coating.

August 1, 2016

Case Study

Packaging a Solution for an Electronics Manufacturer

An electronics manufacturer cleaned up its operation by switching to packaged PMF adhesives.

August 1, 2016

Identifying the Right Adhesive Processing Equipment for the Job

The right processing system can be the difference between a part made correctly and a costly error.

August 1, 2016

Employers Should Brace for a Big Impact from New OSHA Rules

Businesses that don’t prepare for the new OSHA guidelines could be facing increased scrutiny, as well as extra expenses.

August 1, 2016

Ask Dr. Dave

How should we prepare our surfaces for adhesive bonding?

Dave Dunn's August 2016 column.

August 1, 2016

Strategic Solutions

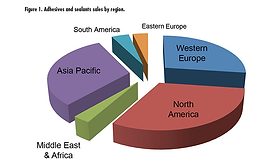

Adhesive and Sealant Market Overview and Outlook

The transportation and construction sectors led adhesives and sealants growth in 2015.

August 1, 2016

Pressure-Sensitive Medical Technology: Challenges and Considerations

Adhesives continue to find applications in the medical and wearable markets.

July 1, 2016

Pressure-Sensitive Adhesives Are in the Driver's Seat

Industrial PSA tapes with high temperature resistance bring new value to production assembly in automotive and transportation markets.

July 1, 2016

Top 5 Trends in Enterprise Labeling for 2016

Demand for color labeling and the expanding role of labeling as a function are among the trends identified in a recent survey.

July 1, 2016

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing