Featured on Home Page

Strategic Solutions

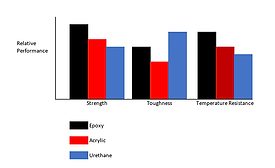

Three key steps must be undertaken when considering the use of adhesives in assembly operations.

Read More

Optimizing Hydrogenated Styrenic Block Copolymers for Adhesives and Sealants

Highly compatible with additives, specialty hydrogenated styrenic block copolymers enable product and process optimization for adhesives, sealants, and coatings formulators.

October 8, 2021

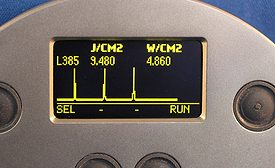

Understanding and Measuring UV LEDs

It is important to consider the variables associated with the LED source and proper measurement tools in order to understand, maintain, and control the adhesive curing process.

October 6, 2021

Naphthenic Specialty Oils Offer Advantages for Sealants

Naphthenic specialty oils provide benefits in terms of their suitability as a replacement for silicone fluids in formulations and their ability to reduce microbial growth in silicone sealant joints.

October 4, 2021

Reconnecting at the Adhesive and Sealant Council’s Convention & EXPO

The week’s events will include a Waterborne Adhesives Short Course, informative technical sessions, an exhibition, the Executive Leadership Conference, and multiple networking opportunities.

September 30, 2021

Case Study

Structural Adhesives are Reaching New Heights with an Innovative Electric Vehicle

Sika serves as the adhesive bonding technology partner for a world record attempt featuring a 100% solar-powered vehicle.

September 28, 2021

Kraton Enters Definitive Agreement to be Acquired by DL Chemical

The all-cash transaction valued at approximately $2.5 billion is expected to close by the first half of 2022.

September 27, 2021

From the Editor

Moving the Adhesives and Sealants Industry Forward

The adhesives and sealants industry relies heavily on distributors for far more than simply raw materials and chemicals shipments.

September 23, 2021

Ask Dr. Dave

Bonding Fluoroplastic Parts to Metals

We manufacture PTFE and other fluoroplastic parts. We have been requested to make parts that can be bonded to metals. Is there a good adhesive, some sort of additive to the PTFE, or a surface treatment that we can use?

September 21, 2021

Hot-Melt Adhesives’ Role in the Packaging Industry Evolution

Adhesives producers are helping to drive a vibrant and continuous innovation journey in the packaging industry.

September 17, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?1633665740)