Featured on Home Page

Case Study

An ongoing, award-winning project highlights next-generation possibilities for the raw materials and chemicals supply chain.

Read More

The Importance of Uniform Light Delivery from UV Curing Systems

Beyond peak intensity and curing area, differences in uniformity can impact the delivered UV light dose and change the optimal setup for flood-curing systems.

September 13, 2021

Strategic Solutions

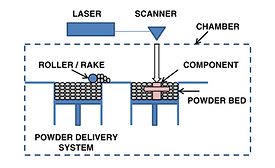

Weighing the Cost Benefit of Complex Design in 3D-Printed OEM Parts

Adhesive bonding opportunities are exponentially increasing with the design complexities of polymer and metal additive manufacturing.

September 10, 2021

Understanding Pressure-Sensitive Adhesives for Graphics Applications

Selecting the optimal pressure-sensitive adhesive for each of the many different—and new—applications across the graphics market is key to helping ensure the end products’ success.

September 7, 2021

2021 Distributor Roundtable

Leaders in raw materials and chemicals distribution share their insights on key issues impacting the adhesive and sealant industry.

September 2, 2021

Arkema to Acquire Ashland’s Performance Adhesives Division for Nearly $1.7 Billion

According to Arkema, the acquisition aligns with the group’s ambition to become a pure specialty materials player by 2024 while supporting Bostik’s strong long-term growth ambition.

August 31, 2021

Composition Adjustments to Drive Polyolefin-Wax Interactions in Hot-Melt Adhesives

The proper interaction between polymer and wax is required to achieve specific properties in hot-melt adhesives.

August 30, 2021

From the Editor

Innovations Abound in the Adhesives and Sealants Industry

From newly developed raw materials and chemicals to finished products and high-tech applications, the adhesive and sealant industry continues to focus on innovation.

August 24, 2021

Shaping the Future Needs of Sealant Formulators

Ingredient selection provides a fresh opportunity to drive value and underpin sealants’ commercial performance with a stronger value proposition.

August 20, 2021

Ask Dr. Dave

Bonding with Differing Coefficients of Thermal Expansion

We have a problem maintaining adhesion to two steel surfaces at divergent temperatures because of the response of materials to thermal conditions when going through heating and cooling cycles.

August 17, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing