Featured on Home Page

A new organic/inorganic composite powder simultaneously simplifies formulas and improves product performance, manufacturing operations, and economics.

Read More

Operations

Next-Generation Acrylic Adhesives Enhance Assembly Operations

New adhesives can meet the rigorous demands of manufacturing commercial vehicles, wind energy equipment and industrial equipment

October 2, 2017

Ask Dr. Dave

Is handling one-component polyurethane adhesives and silicone sealants difficult?

Dave Dunn's October 2017 column

October 2, 2017

New Plastomer Receives Innovation Award

The European Innovation Award was created by The Society of Plastics Engineers and Plastics Europe in hopes to raise awareness about the potential of plastic materials.

September 27, 2017

Top 5 News that Sticks

H.B. Fuller News Again Receives the Most Clicks

For the second consecutive week, news about H.B. Fuller’s acquisition of Royal Adhesives & Sealants received the most reader interest.

September 25, 2017

Aerospace Industry Creating Partnerships in New Design

The new designs are focusing on improving fuel efficiency as well as addressing increasingly high material cost.

September 20, 2017

Top 5 News that Sticks

H.B. Fuller Acquisition News Garners the Most Reader Interest

Last week, news about H.B. Fuller’s acquisition of Royal Adhesives & Sealants received the most reader interest.

September 18, 2017

2017 Materials and Chemicals Overview

The coatings, adhesives, sealants and elastomers (CASE) segment is growing at a CAGR of over 5%.

September 1, 2017

Strategic Solutions

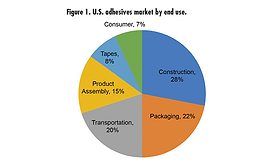

State of the U.S. Construction Market

Total construction spending has been growing at a robust 8.1% over the last five years.

September 1, 2017

Focus on the Future of the Adhesives and Sealants Industry

Key chemical industry topics such as sustainability, acquisition integration, innovation and more will be topics of the ASC Executive Leadership Conference.

September 1, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing