Adhesive Tape Solutions for EV Battery Design

SweetBunFactory / iStock / Getty Images Plus / via Getty Images

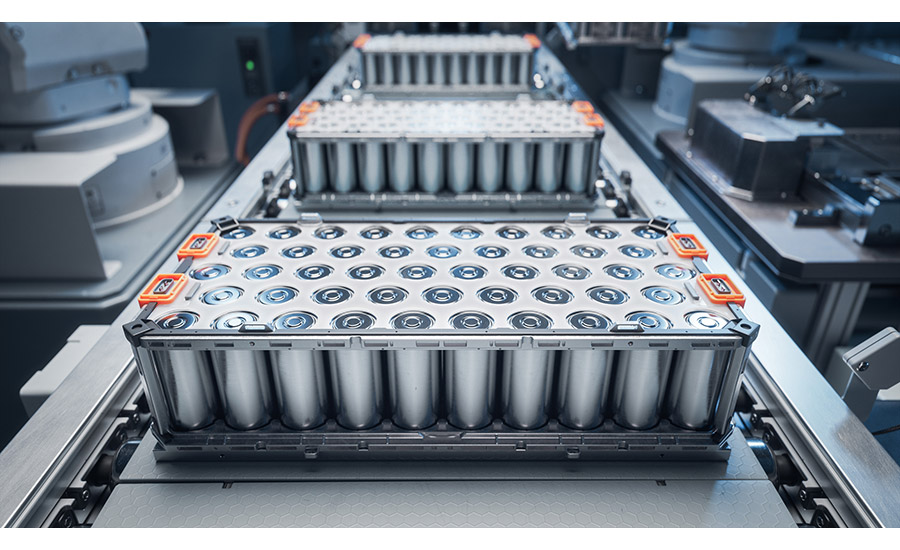

As the automotive industry increases its production of electric vehicles (EVs), it faces unique challenges presented by EV battery engineering. Such challenges include thermal runaway mitigation, providing more effective dielectric insulation to prevent arcing, and designing more efficient assembly of batteries to maximize profitability. Materials such as adhesives, tapes, films, and thermal insulation solutions can contribute to the safety, efficiency, and functionality of battery packs. At the Battery Show North America 2024, Avery Dennison outlined some of the applications for PSA tapes and films in EV battery packs.

Cell Design

EV battery packs typically come in three designs: the pouch design, the cylindrical design, and the prismatic design. The pouch design uses soft, flexible packaging, allowing for lightweight and space-efficient batteries. The cylindrical design has individual cells arranged in a cylindrical shape and is known for its robustness and ease of cooling. With its rectangular shape, the prismatic design is known for its efficient use of space and ease of integration into vehicle chassis. Each design offers different advantages in terms of energy density, weight, and manufacturing flexibility.

These battery cells, known for their delicate nature and high voltages, require robust protective measures. Adhesive solutions play a pivotal role in managing these challenges by offering insulation and physical protection for the cells. Additionally, these solutions are often integrated into larger systems and are crucial for enhancing the performance and safety of the entire battery pack.

Tapes and functional films, label materials, and RFID materials can be used in the battery pack or in the building of the battery pack. They can be a part of cell materials solutions, on either the outside or inside the cells. Tapes and functional films can also offer electrical insulation solutions to protect the electricity of the cell from other conductive components. Additionally, these materials are used in bonding and encapsulation applications, as well as identification and tracking solutions that can be placed on components and communicate with production systems.

Battery Cell Materials

Applications of tapes and films within battery cell materials can include products that facilitate current collecting — material that goes inside the battery cells and acts as the current collector. One such innovation is a metalized polyester film where Avery Dennison metalized copper onto a film This product is intended to replace copper foil, and according to Avery Dennison, the solution is much lighter and safer than copper foil.

PSA cell-wrapping films can provide electrical insulation for arcing within the battery packs. When the high voltages dispersed by cells moves to other components within the pack, the result can be shortened battery life and additional safety issues. Cell wrapping films mitigate these issues. They also provide corrosion resistance, a reliable bonding surface, and desired aesthetics. An alternative to spray coatings, they are thin, durable and offer consistency. An acrylic adhesive in ES 1521 and ES 1421 provides excellent aging resistance and shear strength.

Bonding and Encapsulation

Within the battery pack, the bonding of dissimilar materials and encapsulation of different components is an area where PSA tapes and films can add efficiency and ease of manufacturing. Below are a few examples of materials used for bonding and encapsulation within battery packs.

- Heater films – Used on the cells to heat up the cells when they are at low temperatures, as EV batteries do not perform well under low temperatures. Avery Dennison produces the adhesive that goes next to the film.

- Thermal barriers – These are materials that are placed between cells, creating thermal insulation so that if one cell heats up, the other cells next to it don’t heat up. They also provide a fire barrier.

- Compressor pads – Foam materials are place in between pouch cells, which expand and contract. The foam absorbs that expansion and contraction. These pads are placed using adhesive tape.

Electrical Insulation

The batteries in EVs have a high energy density, which requires technology to prevent electrical arcing within battery packs, which can lead to thermal runaway and short circuits. Among the solutions for electrical insultation within the battery packs are single-sided tapes.

Single-sided tapes can be laminated to different conductive components within the battery pack. A metal cooling plate that cools down the battery cells will have a tape laminated on it to prevent electrical arcing. FT 0031 is a single-coated tape that uses a propriety stretch film and an acrylic adhesive, making it conformable and tear resistant. Used for electrical insulation inside battery packs, it can be applied to different geometry and contours and can withstand metal forming processes.

Identification and tracking

Many automotive components use RFID tracking technology. Because of the safety issues associated with battery packs, there is a heavy use of tracking and communication devices within their components. Avery Dennison creates labels throughout the battery pack such as safety labels and labels communicating other information. RFID labels are used in the raw materials that are going into the battery pack within the supply chain.

Learn more about tape solutions at Avery Dennison by visiting tapes.averydennison.com.

References:

1. Vanraaphorst, M. (n.d.). Materials for Thermal Runaway. Avery Dennison Performance Tapes White Paper. https://yoursolution.tapes.averydennison.com/acton/attachment/5107/f-fedfaf3b-47e1-4012-964f-e82cf06182c3/1/-/-/-/-/PTNA23%20Whitepaper%20Thermal%20Runaway%203May2023.pdf

2. Vanraaphorst, M. (n.d.). Dielectric Insulation for EV Batteries. Avery Dennison Performance Tapes White Paper. https://yoursolution.tapes.averydennison.com/acton/attachment/5107/f-712ace23-9067-4e6d-86ac-93cdc88c33cc/1/-/-/-/-/PTNA23%20Whitepaper%20Dielectric%20Insulation%2028Apr2023.pdf

3. Vanraaphorst, M. (n.d.). EV Battery Pack Assembly Solutions. Avery Dennison Performance Tapes White Paper. https://yoursolution.tapes.averydennison.com/acton/attachment/5107/f-2bd38d41-95c8-4d93-abc0-bd6b2ddd4097/1/-/-/-/-/PTNA23%20Whitepaper%20EVB%20Pack%20Assembly%20Solutions%2023May2023.pdf

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!