Touchscreen Manufacturing with UV LED Curing Technology

UV LED curing technology provides a more consistent and reliable process without damaging or discloring heat-sensitive components.

Ultraviolet (UV) light-emitting diode (LED) curing offers many benefits for bonding and coating applications in the touchscreen manufacturing segment. It provides a more consistent and reliable process without damaging or discoloring heat-sensitive components.

UV curing is a photopolymerization process that uses UV energy to change a liquid to a solid. Upon absorption of the UV energy, the photoinitiator (PI) produces free radicals that initiate crosslinking with binders (monomers and oligomers) in a polymerization reaction to cure or solidify the ink, coating, or adhesive, usually in a few seconds (see Figure 1).

Originally introduced in the 1960s, today’s manufacturers use UV curing for a variety of applications—from graphic arts printing to automotive headlamp coating and more. In fact, the UV curing market continues to grow as it displaces water- and solvent-based thermal drying processes due to increased productivity, higher quality and performance, and environmental benefits.

UV LED Curing Basics

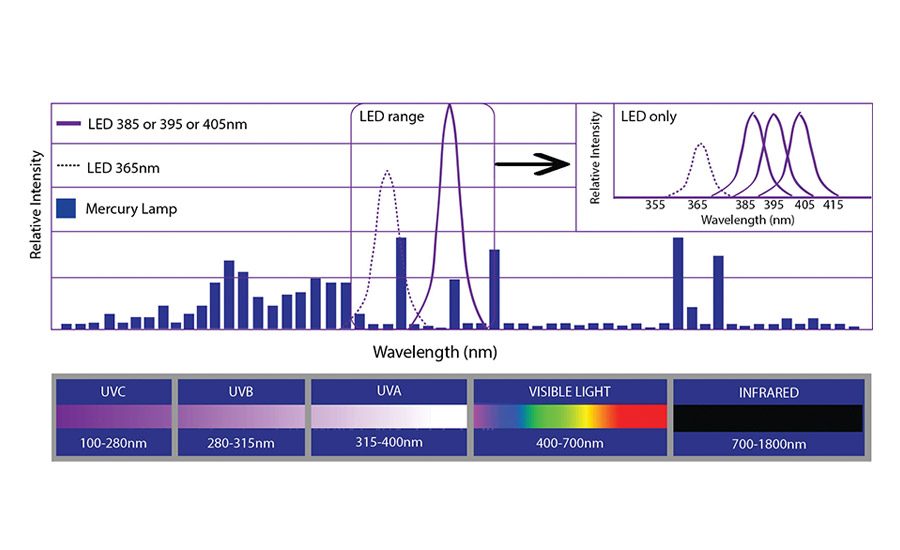

LEDs for UV curing applications generate UV energy in an entirely different way. As an electric current (electrons) moves through a semiconductor device called a diode, it emits energy in the form of photons. The specific materials in the diode determine the wavelengths of these photons. In the case of UV LEDs, the output is typically in a very narrow band (± 10 nm). Figure 2 compares the output of a 395-nm UV LED lamp with a typical mercury arc lamp. It is important to note the difference in intensity and wavelength of the output—both are important to understanding a UV curing process.

UV LEDs have been commercially available for more than 10 years. However, their unique output characteristics require newly formulated UV chemistries in order to take advantage of UV LED’s many benefits. For efficient and effective UV curing of an ink, coating or adhesive, the formulator needs to overlap the UV lamp output with the spectral absorption of the photoinitiator. A very efficient cure is possible with a formulation designed specifically for UV LED curing using a photoinitiator with concentrated absorption in the UV-A range.

UV chemistries for electronics applications are typically acrylates, silicones or epoxy formulations; acrylates are the primary choice because they generally cure more quickly. Many formulations are one-part, which makes handling and application simple. Most UV formulations are 100% solids with no solvent emissions, and are available in a range of viscosities depending on application needs. Shelf life varies from six months to several years.

Some UV formulations, especially those for bonding or encapsulating (where the UV energy cannot reach everywhere due to shadow areas) use dual-cure mechanisms such as UV with heat or moisture curing. UV adhesives can adhere dissimilar materials, such as metal, glass and plastics, with precision dispensing via syringe.

Touchscreens

The touchscreen market continues to grow; uses include smart phones, tablets, eBook readers, mobile game consoles, and in-car navigation systems. Asia-Pacific is the largest and fastest growing regional market for touchscreen manufacturing.

A touchscreen display is an assembly of many different layers, such as the liquid crystal display (LCD) or organic light emitting diode (OLED), glass, conductive and non-conductive layers, and a protective flexible layer. Each of these layers needs a liquid optically clear adhesive (LOCA) to provide a strong bond, a protective seal from moisture, and desirable optical properties while withstanding sunlight.

UV LED-curable adhesive formulations are typically acrylic or epoxy cured at 365 nm, and deliver excellent optical properties such as light transmission, reduced reflections, anti-fogging, and impact and scratch resistance. They are easy to dispense and provide high flexibility without shrinkage or tension between layers, which could cause image distortion.

The manufacture of LCD and OLED displays also uses UV LED curing prior to assembly into a touchscreen. The low heat and on-demand curing using UV LED lamps is especially advantageous for preventing damage to sensitive components and delivering a consistent, high-speed process. One specific application is the edge sealing of OLEDs, which uses an epoxy resin and spot-curing UV LED system to deliver a precise and efficient cure that effectively seals out moisture. UV LED curing offers many benefits to electronics manufacturing, most notably improved yield, process stability and better adhesion.

Yield

Yield (defined as the number of salable units as a percentage of total units produced) is critical in high-volume manufacturing. Assuming a vendor can produce 5,000 displays per hour, a 24 x 7 operation for 50 weeks could produce 42 million displays on a line. A 0.1% yield increase from 98% to 98.1% would be worth 42,000 displays annually. At the competitive prices displays are offered, these extra 42,000 displays could provide significant profit margin to the vendor or allow them to gain market share from their competition.

Yield is improved with UV LED curing systems by providing consistent UV output over long periods of time. The display material receives a homogenous dose of UV energy consistently across the surface with no “hot” or “dead” spots that would lead to rejects.

Process Stability

UV LED systems provide stable output over long periods of time, typically greater than 20,000 hours. At the low power levels needed for display manufacturing, it is conceivable that the UV LED systems would last beyond 40,000 hours, with the only maintenance being monthly checks of air filtration and ensuring the emitting window is clean. Being semiconductor devices, UV LED systems can be turned on and off instantly with no damage to the light source. No warm-up or cool-down period is required.

The consistent output and long life lead to process stability, a key requirement for high-volume manufacturing. Knowing the equipment is consistently producing the same UV output allows vendors to focus their resources on other parts of the manufacturing process. Process stability is further aided by the fact UV LED systems only produce output in the UV-A range, typically 365 nm, to match with the acrylic adhesive being used. Since no UV-C or infrared is being produced, the adhesive and surrounding transport are only receiving the amount of dose in the wavelength required. This UV LED “cold cure” again improves process stability by not damaging the electronic components while the UV adhesive is being cured.

Improved Adhesion

Since UV LEDs provide energy in a narrow band, a wavelength-optimized adhesive can be formulated to ensure deep-through curing and attachment to display surfaces. The adhesive manufacturer can depend on UV LED’s consistent output at a specific wavelength to develop a formulation that is highly reactive to the UV energy and thus shorten the curing time. Future developments of UV adhesives may also mean less adhesive is used for each display screen, leading to an additional cost savings to the manufacturer.

Multiple Benefits

UV LED curing offers electronics manufacturers higher yield rates and productivity due to a consistent and stable process with less damage to heat-sensitive components. UV LEDs require very little space, making them easy to integrate into small spaces. Since UV LEDs produce no ozone emissions or hazardous waste concerns, they are environmentally friendly and safe.

Electronics adhesives and coatings suppliers have formulations available for use with UV LED curing that are easy to handle and apply in the precision, high-speed processes that are so common in electronics manufacturing. Many electronic product manufacturers are already reaping the benefits of using UV LED curing to improve their manufacturing processes.

For additional information, visit www.phoseon.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!