Home » bonding

Articles Tagged with ''bonding''

Pressure-Sensitive Adhesives 101

This article explains what a pressure-sensitive adhesive is, how it is constructed and what adhesive options are available.

October 1, 2009

Adhering to Difficult Substrates with Silicone Adhesives

Substrates with reactive groups available for bonding make chemical bonding easier to achieve, while substrates with nothing to react to make adhesion difficult.

October 1, 2005

Packaging EndUser: Starch- and Dextrin-Based Adhesives

Starch- and dextrin-based adhesives play a large part in industrial production, especially the packaging industry.

August 1, 2005

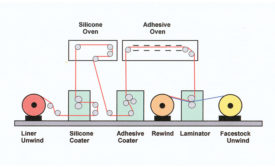

Manufacturing Pressure-Sensitive Adhesive Products: A Coating and Laminating Process

How are pressure-sensitive adhesives made?

April 1, 2005

Epoxy, Acrylic, and Urethane Structural Adhesives

Increasing alternatives to mechanical fastening are available.

September 1, 2004

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing